DTF (Direct to Film) printing is redefining custom tumbler decoration with unmatched versatility, vibrant color payoff, and strong adhesion across various surfaces. Whether you're producing merch, gifts, or promotional items, DTF delivers professional results on stainless steel, plastic, and coated glass tumblers.

This guide outlines everything you need to know about using DTF for tumblers, with expert insights and recommended equipment for the best output.

What is DTF Printing?

DTF (Direct-to-Film) printing involves creating a design on a special PET film using water-based pigment inks and a thermoplastic adhesive powder. The film is then cured and transferred onto the surface like a tumbler using heat. Originally developed for textiles, DTF has evolved with equipment like the STS XPJ-1682D DTF Printer or Mimaki TxF150-75, which are widely recognized in the industry for their consistent results and precision.

Unlike sublimation (which needs polyester coating) or UV printing (which requires flat surfaces and expensive equipment), DTF from dtfsatx.com can apply detailed, full-color prints to a wide range of coated tumbler surfaces quickly and affordably.

Why Use DTF for Tumblers?

Tumblers are not simple surfaces to decorate. They are curved, often metallic or insulated, and require a method that adheres reliably to their smooth finish. DTF is ideal because it:

-

Bonds effectively to powder-coated and treated surfaces

-

Handles fine details and color gradients exceptionally well

-

Requires no weeding or pretreatment

-

Can be used for one-offs or large production runs

Professional heat presses such as the Geo Knight DK3 Mug Press or convection ovens paired with Shrink Wrap Films ensure even pressure and heat distribution for curved surfaces like tumblers.

Benefits of DTF on Tumblers

This process allows:

-

Compatibility with various tumbler materials: stainless steel, plastic, glass

-

Full CMYK+White printing with high-definition resolution (1440x1440 dpi standard)

-

Water, UV, and scratch-resistant finishes with optional lamination

-

No need for polyester coating or sublimation blanks

-

Cost-effective setup for both short and long runs

What Tumblers Work Best for DTF?

DTF is highly versatile but works best on:

-

Powder-coated stainless steel tumblers (20oz, 30oz)

-

Gloss-finish insulated tumblers

-

BPA-free plastic mugs with smooth finish

-

Enamel camping mugs

-

Gloss-coated glass tumblers

Avoid uncoated ceramic or stone surfaces unless pre-treated.

DTF Printing Process for Tumblers

Design Preparation

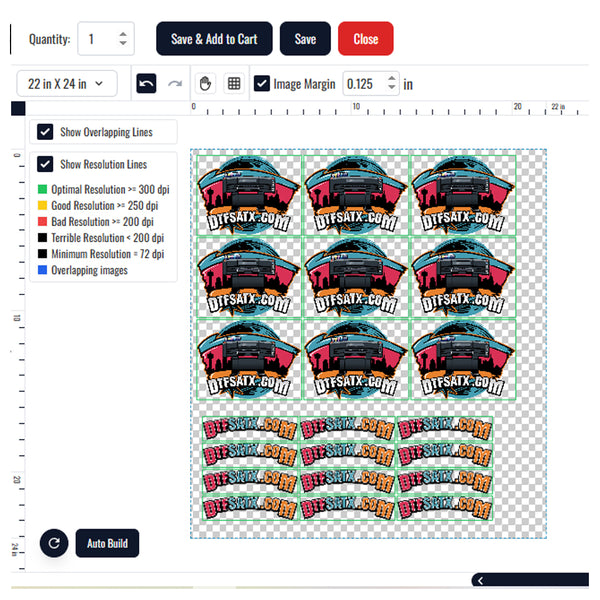

Create high-resolution artwork at 300 DPI using Adobe Illustrator or CorelDRAW. Export in transparent PNG or vector format (SVG, AI, PDF). Ensure the layout is measured precisely for the wrap-around area, accounting for curves.

Printing onto the DTF Film

Print using industrial-grade printers like the STS XPD-724 DTF Printer or Mimaki TxF150 with CMYK+W inks onto PET film rolls. Print in reverse (mirror image) for accurate transfer.

Applying Adhesive Powder

Apply hot-melt adhesive powder (TPU powder) manually or with an automated powder shaker. Shake off excess and cure using a DTF curing oven like the Procolored Curing Oven at 150–160°C for 2–5 minutes.

Applying the Film to the Tumbler

Clean the tumbler surface with 91% isopropyl alcohol. Use heat-resistant tape to secure the cured film to the tumbler. Wrap with a heat-safe shrink wrap sleeve.

Curing in Oven or Press

Place in a convection oven at 160–170°C for 6 minutes, or use a tumbler press such as the PYD Life Tumbler Press. Ensure even pressure and temperature.

Peeling the Film

Cool the tumbler to room temperature before slowly peeling off the PET film. Optionally, press again with a protective silicone sheet for 10 seconds to lock in the design.

DTF vs. Other Printing Methods for Tumblers

|

Printing Method |

Pros |

Cons |

|

DTF |

Universal compatibility, full-color, durable |

Needs film and heat curing |

|

Sublimation |

Deep color, dishwasher-safe |

Limited to poly-coated, light-colored mugs |

|

UV Printing |

Instant cure, fine detail |

High equipment cost, flat surface limitation |

|

HTV Vinyl |

DIY-friendly |

Limited durability and detail |

|

Waterslide |

Good for detail |

Requires sealing and fragile in use |

How Long Does DTF Last on Tumblers?

With proper adhesion and curing, DTF prints can withstand 50+ hand washes without significant fading. Using premium films and lamination, durability can be extended to light dishwasher use. Professional-grade DTF films from brands like DTF San Antonio offer the best results.

Final Take

DTF printing is the future of tumbler decoration. It merges professional-grade output with the flexibility to handle various surfaces and designs. Backed by reliable equipment and materials, it's no longer a novelty but a standard.

Whether you’re running a custom print shop or launching a drinkware brand, DTF offers you quality, efficiency, and longevity that other methods can’t match.