UV DTF (Ultra Violet Direct to Film) printing is transforming mug customization with precise, vibrant, and durable transfers. Whether for corporate branding, personalized gifts, or retail merchandise, UV DTF offers a professional solution that works on virtually any mug surface without the limitations of traditional methods.

This guide, prepared in collaboration with the experts at DTF San Antonio, outlines the full UV DTF process and technical insights to help you get flawless results on ceramic, glass, and metal mugs.

What is UV DTF?

UV DTF stands for Ultra Violet Direct to Film. It uses UV-curable inks printed onto a transparent A film, layered with a laminate B film to create a pressure-sensitive decal. Once printed, the sticker is applied directly to the mug and bonds instantly without requiring heat or specialized coatings.

Unlike sublimation or screen printing, UV DTF is compatible with almost any smooth, non-porous surface. It is widely adopted using professional equipment like the Ricoh Ri 1000 UV DTF System or LEF-12i UV Printers, offering commercial-grade clarity and performance.

Why Use UV DTF for Mugs?

Mugs present curved, coated, or glazed surfaces that can be challenging for other printing methods. UV DTF stickers:

-

Adhere to most mug materials: ceramic, glass, stainless steel, plastic

-

Require no heat pressing or sublimation blanks

-

Support full-color, high-resolution prints

-

Resist water, scratching, and UV exposure

-

Work well for both individual and batch applications

UV DTF is particularly effective for curved surfaces where flatbed UV printers fall short.

Benefits of UV DTF on Mugs

This process offers:

-

Instant application with minimal tools

-

Vibrant colors, smooth gradients, and detailed logos

-

No need for pretreatment or curing ovens

-

Long-lasting adhesion and print quality

-

A versatile workflow ideal for e-commerce, gifting, and on-demand personalization

What Mugs Work Best for UV DTF?

UV DTF stickers are compatible with:

-

Glossy ceramic mugs (11oz, 15oz standard sizes)

-

Glass coffee mugs

-

Stainless steel insulated mugs

-

Plastic or acrylic tumblers with smooth finishes

-

Enamel camping mugs

Just ensure the surface is smooth, clean, and dry prior to application.

UV DTF Sticker Application Process for Mugs

Step 1: Design Preparation

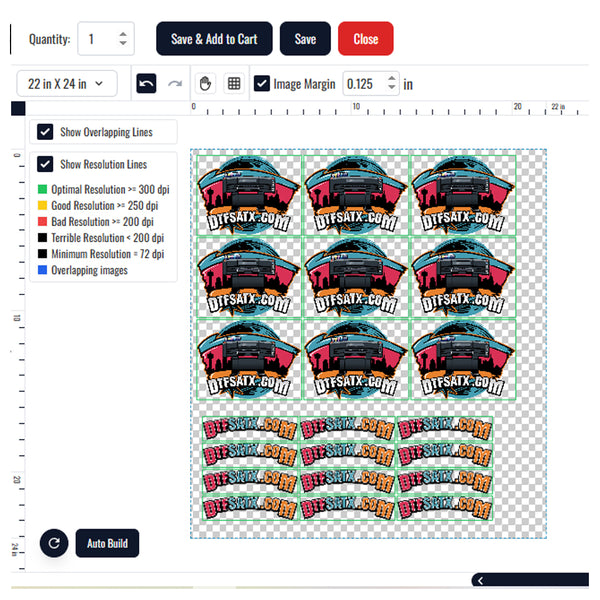

Create a high-resolution PNG file (300 DPI) or vector format (SVG, PDF, AI). Use graphic software such as Adobe Illustrator or Affinity Designer to scale your artwork to fit the mug’s imprint area (typically 2.5–3 inches high by 7.5–8 inches wide).

Step 2: Printing on UV DTF Film

Print your design in reverse onto the A film using UV DTF printers. UV LED light instantly cures the ink layer by layer. Laminate the print with a B film, creating a peelable decal.

At DTF San Antonio, we use industry-grade UV printers for consistent, crisp output.

Step 3: Applying the Sticker

Peel the laminated sticker carefully and align it onto the mug surface. Use a silicone squeegee to apply firm, even pressure, especially over curved areas. Start from the center and work outward to eliminate air bubbles.

Step 4: Finishing (Optional)

Although stickers are cured during printing, a secondary cure using a handheld UV light can increase adhesion and durability. For mugs used frequently or exposed to moisture, apply a UV-safe clear laminate or spray sealant.

UV DTF vs. Other Mug Printing Methods

|

Method |

Pros |

Cons |

|

UV DTF |

Instant cure, works on all surfaces, vivid detail |

Requires precise sticker placement |

|

Sublimation |

Deep color, dishwasher safe |

Requires polyester coating and heat press |

|

Screen Printing |

Good for large batches |

Costly setup, limited detail |

|

Vinyl |

Easy DIY |

Less durable, not waterproof |

|

Waterslide |

Flexible for odd shapes |

Fragile, requires sealing |

How Long Do UV DTF Stickers Last on Mugs?

UV DTF stickers from DTF San Antonio are rated for over 100 hand washes when applied correctly. They resist fading, cracking, and UV exposure. For best results, hand wash mugs and avoid microwaving. Optional laminates can extend durability further.

Final Take

UV DTF stands as the go-to solution for high-quality, full-color mug decoration. It bridges the gap between short-run flexibility and commercial-grade results. Fast, reliable, and compatible with nearly all surfaces, UV DTF empowers creators, retailers, and brands alike.