Sublimation paper plays a critical role in creating vibrant, permanent prints on polyester fabrics and coated surfaces. If you're a printing enthusiast, hobbyist, or small business owner, understanding how sublimation paper works can significantly improve your results.

What Makes Sublimation Paper Unique?

Sublimation paper holds sublimation dye ink and releases it onto substrates under heat. It's not ordinary copy paper, and using it properly makes all the difference in your printing outcomes.

-

Engineered with a special polymer coating for ink retention

-

Transfers ink into the substrate, not just onto it

-

Designed for use with polyester fabrics and coated items

-

Used in tandem with heat presses for permanent application

-

Produces high-definition, full-color images without peeling or cracking

How Sublimation Paper Works in the Printing Process

Sublimation paper facilitates a unique printing process where dye turns into gas and bonds with materials at a molecular level.

This produces long-lasting, high-quality results ideal for custom merchandise. To learn more about sublimation versus other printing methods, read the detailed guide on DTF vs sublimation printing.

The Sublimation Printing Process

Sublimation printing starts by creating a digital design, usually with software like Adobe Photoshop or Illustrator. That design is printed in mirror image using a sublimation printer and special sublimation ink.

Once printed, the design is transferred using heat to a compatible substrate.

The Role of Heat

Heat is essential to the sublimation process. It activates the dye ink, transforming it from a solid to a gas without passing through a liquid stage. This gas penetrates the polyester fibers or polymer coating of the blank material, embedding the design.

Printer Compatibility

You must use a sublimation printer, such as those from Epson or Sawgrass, with sublimation ink. Regular ink or laser printers are not compatible and may damage the sublimation paper or ruin your project.

Single-Use Design

Sublimation paper is designed for one-time use. After a transfer, most of the dye ink is fully released. Attempting to reuse it will lead to faded, incomplete images with poor color saturation.

Identifying the Print Side

Most sublimation papers have a clearly marked back side, often with a watermark. Always print on the bright white, unmarked side. This ensures proper ink transfer during pressing.

Ideal Heat Press Settings

The best results typically come from pressing at 385 to 400 degrees Fahrenheit for 40 to 60 seconds. However, the exact settings can vary depending on your blank material. For detailed instructions, refer to our sublimation dye application instructions.

Types and Best Uses of Sublimation Paper

Different sublimation papers are designed for various applications, depending on drying speed, ink absorption, and substrate type. Choosing the correct paper will dramatically affect your output quality.

Fast-Dry Sublimation Paper

Fast-dry sublimation paper, usually 105 to 120 gsm, is ideal for high-speed production. It dries almost instantly and is best suited for polyester clothing and projects requiring a quick turnaround without sacrificing detail.

Tacky Sublimation Paper

Tacky paper is perfect for stretch fabrics like spandex or activewear. Its slight adhesive surface prevents shifting during pressing, which helps avoid ghosting or misalignment in your prints.

High-Release Sublimation Paper

These papers offer exceptional ink transfer, leaving almost no residue on the paper after pressing. They are ideal for high-saturation prints and hard materials like ceramics or metal signage.

Heavyweight Sublimation Paper

With a thickness above 125 gsm, heavyweight paper reduces curling and is best for rigid items or large-format prints. It handles heavy ink loads well and maintains structure in humid environments.

ECO Sublimation Paper

ECO sublimation paper is a more affordable option for bulk printing. It works best for high-volume runs where cost efficiency is a priority, although it may compromise slightly on ink retention.

Best Paper for Mugs and Tumblers

Choose paper sizes and weights that match the shape of your drinkware. For example, 125 gsm paper sized 8.5 x 11 inches works great for 20 oz tumblers, while larger sizes like 11 x 17 inches are suited for 30 oz tumblers.

Preventing Sublimation Paper from Sticking

Use protective layers like butcher paper or Teflon sheets during pressing. Preheating your substrate and allowing it to cool before peeling off the paper can also prevent sticking and ghosting.

Additional Insights to Improve Your Sublimation Results

Mastering sublimation printing involves more than just choosing the right paper. Understanding your entire workflow, from design to post-press care, can dramatically improve consistency and quality.

Optimal Drying Time

Let your sublimation paper dry for at least 10 to 15 minutes after printing before pressing. This ensures that the ink has fully set and reduces the risk of smudging or vapor-related sticking.

Useful Application Tools

Using heat-resistant tape instead of spray adhesive is safer and cleaner. Tape holds your design firmly in place without risking residue or over-adhesion during pressing.

Importance of Pre-Pressing

Pre-pressing removes excess moisture from fabrics or coated items. This is crucial in humid environments, where moisture can interfere with ink transfer and cause bubbling or sticking.

Removing Paper Residue

Use rubbing alcohol or a solvent-safe cleaner to remove any leftover paper fibers. Be gentle to avoid damaging the transferred design, especially on hard substrates.

Common Beginner Mistakes

Always use the correct side of the paper, set the press to proper temperature and time, and test on scrap materials before launching a full production run. Learning these habits early saves materials and boosts your print confidence.

Testing Multiple Brands

Different brands of sublimation paper offer varying results. Try trusted names like A-SUB, TruePix, or HTVRONT, and match them with your printer type to find the best balance of quality and cost.

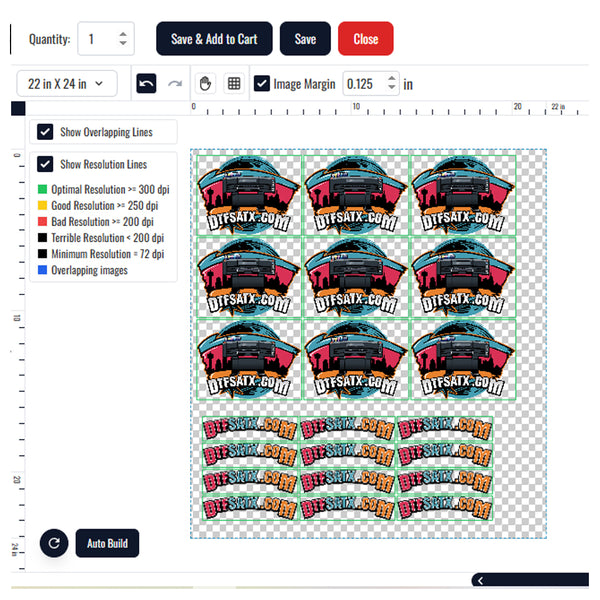

Efficiency with Gang Sheets

Gang sheets let you print multiple designs on one large sheet, reducing waste and improving productivity. At DTF San Antonio, we make this process easy with high-quality transfers and professional handling.

Key Takeaways for Choosing the Right Sublimation Paper

Choosing the right sublimation paper can elevate your print quality and minimize frustration. Match the paper to your printer and project type to ensure professional results every time.

-

Use fast-dry paper for speed and ease

-

Choose tacky paper for stretchable fabrics

-

Go with high-release paper for bold, hard goods

-

Select heavyweight paper to minimize curling

-

Only use sublimation paper with sublimation printers and ink

Conclusion

Sublimation paper is more than just a tool; it's the foundation of every successful sublimation project. Whether you're personalizing apparel, customizing mugs, or producing bulk gang sheet orders, using the right paper ensures vibrant, permanent, and professional-looking prints.