Caps are used widely because they are compact, visible, and surprisingly high-impact. But there is nothing better than custom-printed caps. However, printing on caps is tricky due to the curved surface, thick fabric, and stitched panels. No worries!

DTF printing can solve all these issues and provides full-color possibilities. Let's see why DTF is quickly becoming the go-to for custom caps in 2025 and how it works.

Why Have Caps Always Been a Headache to Print On?

Before DTF, custom cap printing relied mostly on embroidery, screen printing, or vinyl heat transfers, but comes with downsides:

-

Embroidery looks good and durable, but it limits design detail and color. It also adds weight to the front panel, which can distort the shape.

-

Screen printing struggles on curved surfaces, and fine lines or gradients do not apply well on them.

-

Vinyl looks good at first, but usually peels or cracks after multiple washes or on textured fabrics.

DTF fixes all of these issues by offering sharp, detailed designs that feel soft, hold strong, and look good across a variety of cap styles.

What Is DTF (Direct to Film) Printing?

DTF stands for Direct-to-Film, and it differs from screen printing or direct-to-garment (DTG). DTF prints your design onto a special film using water-based inks and a layer of adhesive powder. That film is then heat-transferred onto your cap using a heat press.

What makes it perfect for headwear is the versatility and flexibility of the transfer. You're not printing directly onto a curved surface; you are printing onto a film, then bonding that design to the cap with heat and pressure. This ensures clearer lines, sharper edges, and less warping.

Why does DTF Works So Well on Caps?

DTF works on any fabric from cotton, polyester, to canvas blends. The film develops a sticker that sticks to pretty much anything. DTF handles the fine text, gradients, full-color logos, and photorealistic graphics.

Unlike vinyl, DTF transfers flex with the fabric. This matters for hats, which get tossed around, stuffed into bags, or stretched onto different head sizes.

The best part is the short turnaround time; once the transfer sheet is ready, you can press dozens of caps in minutes. Even if you don’t need multiple screens, specialty thread, or expensive embroidery heads. Just your design, a roll of PET film, adhesive powder, and a heat press. To get the best DTF stickers for caps, visit DTF Printing San Antonio.

Cap Styles That Work Well with DTF

You can DTF-print onto most cap types, including:

-

Dad hats (low-profile, cotton)

-

Trucker caps (poly front, mesh back)

-

Snapbacks (flat-brimmed streetwear style)

-

5-panel and camper caps

-

Performance

Just make sure the front panel is pressable and heat-safe. Structured caps with reinforced brims or thick seams may require careful placement.

DTF Printing Process for Caps

Here is the step-by-step process for direct-to-film printing on caps:

Design Preparation

Before printing, you need a clean, high-resolution design in a transparent PNG or vector file (SVG, AI, PDF). Make sure it's at 300 DPI for print clarity. If you are designing for a dark tote, a strong white underlayer can help colors pop.

Make sure to scale your design exactly to fit the cap area. Measure your printable space and design accordingly.

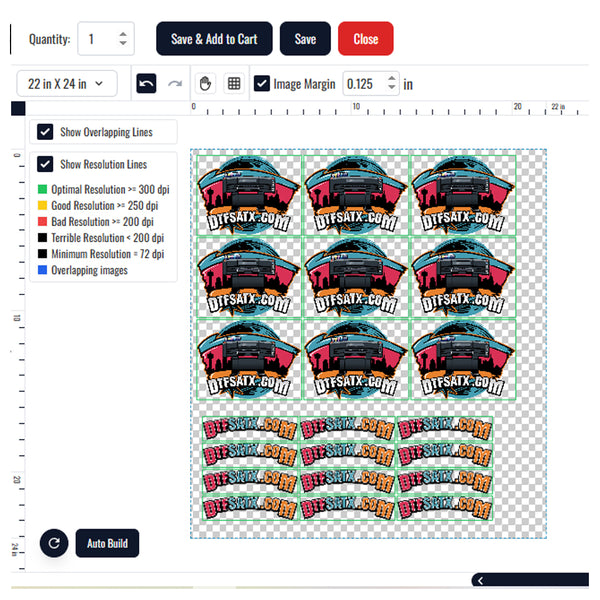

Printing onto the DTF Film

With your design ready, the next step is printing it onto a special PET DTF film.

-

A DTF printer uses water-based pigment inks and prints the design layer by layer.

-

First, the printer lays down the CMYK colors.

-

Then it adds a layer of white ink underneath.

Applying the Adhesive Powder

When the print is still wet on the film, apply DTF hot-melt adhesive evenly on the design. The powder sticks only to the inked areas and falls off the rest.

Melting the Powder

Now, melt the adhesive powder to prepare a bond with the fabric. You can do so in a curing oven or under a heat press at around 150–160°C (300–320°F) for 2–5 minutes.

Don't press the cap; only cure the powder until it turns into a slightly glossy, rubbery finish. Now it becomes a ready-to-transfer sticker sitting on the film.

Heat Pressing the Cap

Now comes the main step of transferring the cured film onto your cap. Simply, pre-press your cap for a few seconds to remove any moisture. Then, place the film face down on it.

Set your heat press to 160–170°C (320–340°F) temp for 15–20 seconds and apply even pressure. Now it sticks to the desired area.

Peeling the Film

Let the cap fabric cool down completely, and then peel the film slowly and smoothly. Now you get the clean, vibrant print fully fused into the fibers.

You can also press again by placing the Teflon sheet over the design and pressing again for 10 seconds to lock the design there.

Final Words

DTF works best for cap customization, and every business can benefit from it. You get the look of high-end, full-color graphics with the flexibility and durability that modern headwear demands. There is no cracking, warping, or limits on creativity.