Custom tote bags are in trend, some used for influencer giveaways or others for eco-friendly branding. However, not all printing methods suit the fabric of tote bags. If you want bold, vibrant designs that last through daily use and multiple washes, you need DTF (Direct to Film) printing.

It can change the game for businesses, artists, and hobbyists who print on textiles, especially cotton, canvas, and blends like the ones used for tote bags. Find out here how DTF printing is the perfect choice for tote bags.

What is DTF Printing?

DTF stands for Direct-to-Film, and it differs from screen printing or direct-to-garment (DTG). DTF prints your design onto a special film using water-based inks and a layer of adhesive powder. That film is then heat-transferred onto your tote bag using a heat press. It works well on light or dark fabrics, handles detailed designs like a pro, and doesn’t crack or fade easily.

Why Use DTF for Tote Bags?

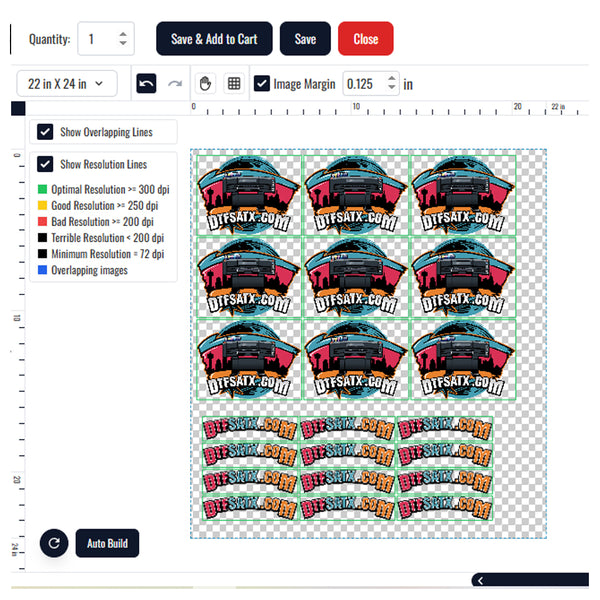

Tote bags are not like T-shirts. They are usually made from heavier cotton, canvas, or jute, which means they don’t take ink the same way as soft tees, and DTF handles the job best. Plus, whether you are printing 1 or 1,000 tote bags, DTF is fast, reliable, and cost-effective. To get the best DTF stickers and gang sheets, visit DTF San Antonio.

Benefits of DTF on Tote Bags

-

This works well on any fabric and color without pretreatment.

-

Offers you vibrant prints and are highly durable under stress because totes get stuffed and stretched.

-

Provides sharp details, so it is great for logos, fine lines, or small type.

-

Low setup cost for short runs without screens or mess.

What Materials Work Best For DTF?

DTF works great on:

-

100% cotton tote bags

-

Canvas (common for heavy-duty totes)

-

Cotton-poly blends

-

Recycled fabric bags

DTF Printing Process for Tote Bags

Here is the step-by-step process for direct-to-film printing on tote bags:

Design Preparation

Before printing, you need a clean, high-resolution design in a transparent PNG or vector file (SVG, AI, PDF). Make sure it's at 300 DPI for print clarity. If you are designing for a dark tote, a strong white underlayer can help colors pop.

Make sure to scale your design exactly to fit the tote bag area. Measure your printable space (usually around 8–10 inches wide) and design accordingly.

Printing onto the DTF Film

With your design ready, the next step is printing it onto a special PET DTF film.

-

A DTF printer uses water-based pigment inks and prints the design layer by layer.

-

First, the printer lays down the CMYK colors.

-

Then it adds a layer of white ink underneath.

Applying the Adhesive Powder

When the print is still wet on the film, apply fine thermoplastic powder called DTF hot-melt adhesive evenly on the design. The powder sticks only to the inked areas and falls off the rest.

Melting the Powder

Now, melt the adhesive powder to prepare a bond with the fabric. You can do so in a curing oven or under a heat press at around 150–160°C (300–320°F) for 2–5 minutes.

Don't press the bag fabric, only cure the powder until it turns into a slightly glossy, rubbery finish. Now it becomes a ready-to-transfer sticker sitting on the film.

Heat Pressing Onto the Tote Bag

Now comes the main step of transferring the cured film onto your tote bag.

-

First, pre-press your tote bag for a few seconds to remove any moisture.

-

Then, place the film face down on the tote.

Set your heat press to 160–170°C (320–340°F) temp for 15–20 seconds and apply even pressure. Now it sticks to the tote bag.

Peeling the Film

Let the bag fabric cool down completely, and then peel the film slowly and smoothly. Now you get the clean, vibrant print fully fused into the fibers.

You can also go for a second press by placing the Teflon sheet over the design and pressing again for 10 seconds to lock the design there.

DTF vs. Other Printing Methods For Tote Bags

|

Printing Method |

Pros |

Cons |

|

DTF |

No fabric limitations, crisp detail, long-lasting |

Needs film, heat press |

|

Screen Printing |

Good for bulk, vibrant on light fabrics |

Costly setup, not great for fine detail |

|

DTG |

Great for soft garments, no film needed |

Struggles on canvas, needs pretreatment |

|

HTV (Heat Transfer Vinyl) |

Good for names/logos |

Limited detail, more labor-intensive |

How Long Does DTF Print Last on Tote Bags?

DTF prints are built to last. You can expect:

-

50+ wash cycles with minimal fading

-

No cracking or peeling (if applied properly)

Final Take

If you are printing on tote bags in 2025 and not using DTF, you are not providing quality-oriented and durable tote bags. Whether you run a small brand, a print shop, or run merch for an event, DTF gives you the most durable and versatile results. I hope you understand DTF is not optional but a standard.