Custom drinkware is one of the fastest-growing niches in printing, and UV DTF ultraviolet direct-to-film is a convenient and trendy method for tumblers, cups, and glassware. Is your print shop also looking to add or upgrade a drinkware line? This guide is for you!

What Is UV DTF Printing?

UV DTF (Direct to Film) printing uses a UV printer and UV-curable ink onto a specialized transfer film. The inks are cured instantly by UV light, and the transfer will stick easily onto glass, plastic, metal, ceramics, and a lot of other smooth surfaces. Unlike heat transfer vinyl or sublimation, you don’t need heat presses or coated blanks. The simple application relies on peeling, sticking, and curing, and it's done.

For print shops, this method is faster than sublimation or screen printing. Plus, UV DTF transfers produce long-lasting, waterproof, scratch-resistant prints.

Benefits of UV DTF for Tumblers, Cups, and Glass

Adding UV DTF printing to your shop offers a few clear advantages:

Fast Turnaround

UV DTF printing eliminates a lot of the prep work, as there is no need for pre-coating cups or dealing with heat presses. Once the design is printed and cured, you can transfer and move to the finished product in minutes. Print shops can even keep bulk UV transfers.

Durability

UV DTF decals are scratch and water-resistant, and do not fade easily. When applied to tumblers or glassware, they handle everyday use and hand washing better than vinyl.

High-Quality Graphics

You can get vibrant colors, fine detail, and full-wrap capability. Perfect for custom logos, photo-quality artwork, and complex patterns.

Easy Application

The peel-and-stick process eliminates the learning curve of sublimation or powder-based methods. Even small shops can train staff quickly.

Step-by-Step UV DTF Printing Method

If you are setting up UV DTF for tumblers and cups, here’s the easy process:

Step#1: Design Your Artwork

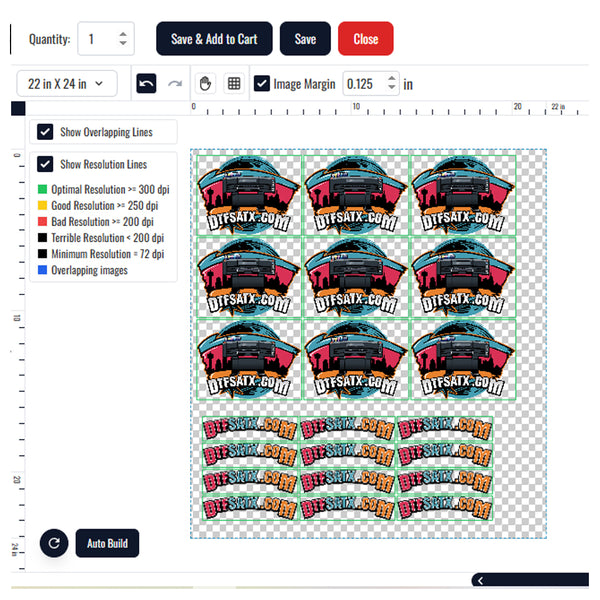

You need to create your art at actual size with 300 DPI resolution. Add 3–5 mm bleed for full wraps and use vector logos when possible for sharp results.

Step#2: Print on UV DTF Film

Now take out your UV DTF printer and use UV-curable inks. Print on AB film or the specific film your supplier provides. Many printers allow inline lamination for easier transfer.

Step#3: Cut and Trim

After printing, trim the film to fit your tumbler, cup, or glass, and for this, you can use digital cutters to contour-cut for shaped decals.

Step#4: Prep the Surface

Clean the surface of the tumbler or glass with isopropyl alcohol to remove all dust, oils, and fingerprints. Then let the surface dry fully before applying.

Step#5: Apply the UV DTF Decal

Now, peel the backing slowly and align the film carefully on the drinkware. Use a squeegee or felt applicator to smooth from the center out. Then peel away the carrier film at a low angle. For extra abrasion resistance or gloss effects, you can add a clear topcoat or compatible sealant.

Tips for Applying UV DTF to Tumblers and Glassware

Here are a few tips that can ensure results:

-

A cold tumbler or glass can make the adhesive stiff. So, warm the surface with a heat gun on low, or even you can hold it in a warm room to help the transfer grip better.

-

When wrapping around steep curves, add small relief cuts to the carrier film. This prevents wrinkles and lets the decal lie flat without stretching.

-

Avoid touching the adhesive because oils from your fingers can weaken adhesion. Handle by the edges or wear gloves when peeling and applying the transfer.

-

For large designs, lay the tumbler on its side and roll it slowly onto the decal. This keeps tension even and reduces misalignment.

Common Problems With UV DTF and How to Fix Them

Let's find out how to fix the common problems:

Edge Lifting

The major cause for this is poor cleaning or incomplete pressure, and you can fix this by re-cleaning, squeegeeing edges, and applying an edge seal if needed.

Bubbling

Bubbling is caused by trapped air during application. epply the film using the slow, center-out technique. Use a pin for micro-bubble release if necessary.

Color Mismatch

The reason is incorrect RIP or film/ink combo. Simply fix it by using correct ICC profiles and consistent materials.

Poor Adhesion

Poor adhesion is due to an incompatible substrate or residue. So, it's better to test different films and ensure surface prep is thorough.

Design Tips for Better UV DTF Drinkware Printing

-

Avoid super-thin lines near edges that may lift.

-

Keep key text and logos away from seams on wraps.

-

Use bold, high-resolution artwork to make the most of the full-color process.

-

Always test print a sample before running a big batch.

Cost and Profitability of UV DTF for Drinkware

For print shops or small businesses, a blunt truth is that UV DTF printers are more expensive than a vinyl cutter, but you save on ovens and extra curing equipment. If we consider the consumable costs, transfer film and inks are affordable per unit, making UV DTF competitive with sublimation.

You can produce dozens of tumblers or cups per hour, depending on staffing and application speed. Just because the finish is high quality, you can charge premium rates.

Should Your Print Shop Add UV DTF for Tumblers and Cups?

If your customers want custom cups, glassware, and tumblers with full-color wraps, UV DTF is one of the best methods available. It’s quick, durable, and scalable without the steep learning curve of sublimation.

Start with a sample kit, test a few sizes of tumblers and glass, and test for waterproofing. Once you see how it performs, you can confidently go for it.