An innovation in printing technology is UV DTF, which everyone wants to opt for. No doubt it's a game-changing opportunity for a printing business, but there’s always the big question: What is the cost of UV DTF in 2025, and is the investment worth it?

Let’s break down the full picture of UV DTF printing costs in 2025 so you know what to expect before making the leap.

How UV DTF Printing Works

UV DTF printing uses a two-step process. First, you can print a design onto a special film using UV-curable inks. These inks don’t dry until exposed to ultraviolet light. After printing, an adhesive layer makes the transfer possible. After the film application to the final surface, expose it to UV light, and the inks cure instantly, locking in a vibrant, durable image.

The main advantage compared to traditional DTF is versatility. Classic DTF is mostly used on fabrics, but UV DTF works on both soft and rigid surfaces. That means one setup can handle phone cases, mugs, tumblers, signage, apparel, and more.

Initial Investment Cost of UV DTF

Printer and Setup

The printer is the main component that costs more. Expect:

-

Expect to pay for entry-level UV DTF printers around $5,000–$10,000, which are good for startups and small shops.

-

Mid-range systems cost 10,000–15,000 as they can handle moderate demand with better features.

-

Commercial-grade printers cost around $15,000–25,000+ for high-volume production.

Other setup costs include:

-

Heat press: $300–2,000

-

Curing oven or UV curing station: $1,000–5,000

-

Software and RIP licenses: $200–500

-

Pre-treatment equipment, if needed

After considering this, a realistic startup budget for a small UV DTF operation in the US ranges from $8,000 to $30,000, and it depends on the scale you choose.

Material and Consumable Costs

Consumables are the ongoing costs that directly affect profitability.

Ink

UV-curable inks cost $40 to $200+ per liter. It depends on brand, quality, and whether it’s OEM or third-party. White ink costs more than standard CMYK colors.

Consumption varies by design, but most small to medium prints use 1–3 ml of ink. That means your ink cost lands roughly between $0.10 and $0.50 per print.

Film and Adhesive Powder

The price of transfer film is $0.30–1.00 per print, and the adhesive powder price is around $0.05–0.15 per print.

Operational Expenses

Labor

US print shop operators in 2025 earn almost $15–25 per hour, depending on region and skill. For cost modeling, assume that labor adds $0.50 to $1.50 per item in small runs. Larger shops with streamlined workflows can push that cost lower.

Maintenance

Many newbies underestimate costs. Routine maintenance includes:

-

Printhead replacement: $300–1,500 (every 6–12 months, depending on use)

-

UV lamps or LED modules need replacement every 1–2 years

-

Cleaning kits, flushing fluids, filters

-

Annual service or calibration is around $500–2,000

Consider a budget of almost $1,000–5,000 annually to keep equipment in top condition.

Cost Comparison with Other Printing Methods

|

Method |

Equipment Cost |

Strengths |

Limitations / Extra Costs |

Best For |

|

UV DTF |

Mid-range (varies by size, often less than DTG) |

Works on more surfaces, instant curing, versatile applications |

Ink/film costs, newer tech (learning curve) |

Small to medium batches, wide variety of products |

|

Traditional DTF |

$2,000–10,000 (cheaper upfront) |

Affordable equipment, good for fabrics |

Mostly limited to fabrics, the transfer step is required |

Apparel printing, entry-level businesses |

|

DTG |

$10,000–30,000+ |

High-quality prints on garments |

Inks $2–10 per shirt, mandatory pre-treatment, slower speed |

Premium apparel, short runs |

|

Screen Printing |

High setup cost upfront |

Great for large-volume runs (200+), durable prints |

Not cost-effective for small batches, limited colors |

Bulk orders, simple designs |

Cost-Saving Strategy for UV DTF Printing

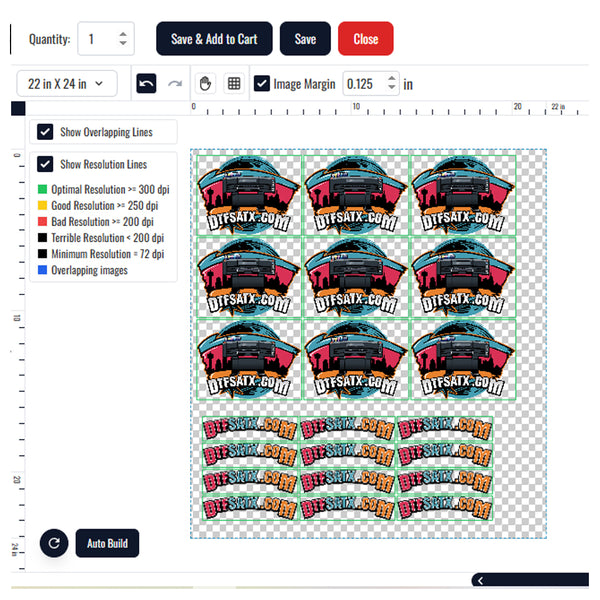

One of the smartest ways to cut costs in UV DTF printing is through bulk purchasing and efficient material sourcing. Instead of buying small packs of transfers or stickers at retail prices, businesses can save significantly by ordering gang sheets or bulk stickers from suppliers like DTF San Antonio. Here’s why this makes sense:

-

Buying in bulk reduces the per-print or per-sticker price. It helps you stretch your margins.

-

With gang sheets, you can place multiple designs on a single sheet, cutting down film usage and setup time.

-

Stocking up reduces the risk of delays when you land a big order.

-

Suppliers like DTF San Antonio often offer discounts for bulk orders, seasonal sales, or loyalty perks. Taking advantage of these can shave off a big portion of your material expenses.

Is UV DTF Printing Worth the Investment?

Yes, it is, most businesses that invest wisely see returns within 6–18 months. Here’s why:

-

Production costs: $1.50–5.00 per item on average

-

Retail pricing: A 3x–5x markup is common in custom printing

-

Profit margins: 50% to 300% depending on product type

For example, a $5 custom tumbler can easily retail for $25–40. Even with overhead, the margins are strong.

Final Thoughts

Starting with UV DTF printing in 2025 isn’t cheap, but it provides a high return on investment when you price your products smartly and manage operations efficiently. Expect $8,000–30,000 upfront, depending on scale, and ongoing costs that average $1.50–5 per print. I hope you now understand the cost of UV DTF Printing for your business.