There are two entirely different approaches for custom apparel printing, and they can leave even professionals scratching their heads: Direct-to-Film (DTF) and Direct-to-Garment (DTG). Both promise vibrant colors and on-demand production, but which one truly fits your needs?

For this, you need to spend a few minutes here to learn the difference as we help you decide the best path for your business or personal projects.

What is Direct To Film Printing DTF?

Those who are asking what DTF transfers are, it is a modern method of printing designs onto a PET film through a DTF printer. Check the top DTF printers. Then you can transfer the print from film to fabric with a heat press to cure it. DTF provides highly detailed, vibrant images on various fabric types such as cotton, polyester, blends, or even nylon.

DTF printing is especially useful for small businesses, custom t-shirt brands, and creators who need vibrant, durable designs without investing in bulk production or costly equipment.

What is Direct to Fabric Printing DTG?

A Direct to Garment DTG printing method is quite different from DTF as it involves pretreatment of dark fabrics. However, it works like a regular printer works on paper. The method begins by pre-treating the fabric, followed by directly printing the design onto the garment, and finally curing the ink with heat.

DTG is highly preferable for 100% cotton fabrics and provides full-color designs with a soft, breathable finish. It's an ideal choice for independent clothing brands and custom print shops that require high-resolution prints for short runs.

What are the Differences Between DTF and DTG Printing?

Dig into the detailed difference between DTF transfers and the DTG printing technique:

Fabric Compatibility

DTF printing offers a flexible approach to fabric. It works best on a wide range of fabrics such as cotton, polyester, nylon, blends, leather, and more. You can use this method to print on diverse product types like sportswear, hats, or even bags.

Whereas, DTG printing works best on 100% cotton or high-cotton blends. Synthetic fabrics like polyester are challenging for DTG because the water-based inks struggle to bond properly.

Print Quality & Color Vibrancy

With DTF, you can get vivid colors with strong opacity, even on dark and colored garments, because white ink layers pop nicely without much effort.

DTG is perfect to get realistic detail like an image and fine gradients, especially on light-colored cotton garments. However, colors on dark garments require a proper pretreatment and multiple ink passes to stay vibrant.

Hand Feel & Texture

DTF designs sit on top of the fabric and provide a slightly raised, rubbery feel if the fabric is thin. This is noticeable when you run your fingers across the design.

In comparison, DTG provides a soft-hand feel because the ink soaks into the fibers. When you touch the print, it provides a real soft feel, and there will be no raised design.

Durability & Wash Resistance

DTF prints are extremely durable as they can endure 50+ washes without cracking or fading, due to the high-quality of the adhesive bond. Whereas, DTG prints are reasonably durable but start fading after 30-40 washes if not properly cured or maintained.

Setup Time & Workflow

DTF involves a few extra steps like printing on film, powder application, curing of powder and lastly heat pressing onto the garment. This can add time if you are printing just one or two shirts. See the process of DTF Printing.

DTG involves less setup once the garment is pretreated. You load the shirt, print, and cure, making it faster and easier for one-off or custom prints.

DTF & DTG Cost Per Print

Suppose, you are living in Texas, Direct-to-Film printing costs between $1.50 and $5.00 per print, which depends on design, size, and order volume. Consumables like ink and film also increase the cost because the ink price can range from $80 to $150 per liter, and transfer films costing $0.50 to $2.00 per sheet.

Direct-to-Garment printing costs vary based on garment color and design details; light-colored shirts may cost $0.10 to $0.20 per print, and dark-colored garments require a white ink underbase and pretreatment, which can increase costs to approximately $0.75 to $0.85 per print.

A Quick Comparison Between DTF Vs. DTG

|

Factor |

DTF |

DTG |

|

Fabric Compatibility |

All textiles (cotton, polyester, blends, nylon, leather) |

Best on cotton & blends; limited on synthetics |

|

Hand Feel |

Slightly raised—the print sits atop the fabric |

Ultra-soft as the ink penetrates fibers |

|

Color Vibrancy |

Bold, opaque whites & bright colors |

Exceptional detail, slightly muted on darks |

|

Durability |

Very high wash resistance (>50 washes) |

Good, but may fade after 30+ washes |

|

Setup Time |

Moderate Film + powder + curing |

Low Just pretreat and print |

|

Maintenance |

Low Standard printer upkeep |

High maintenance, daily head wipes & periodic deep cleans |

|

Cost Per Print |

Lower for dark & polyester orders |

Higher for dark garments (white ink use) |

|

Minimum Order |

No minimum order |

No min, ideal for one-offs & quick prototypes |

Why Should You Choose DTF?

You can choose DTF printing if you need maximum fabric flexibility, like sportswear, bags, nylon jackets, or if you are handling medium to large runs and want consistent color across batches. Moreover, if you want to minimize garment pretreatment steps and are low on budget to start a business, you can go for DTF transfers.

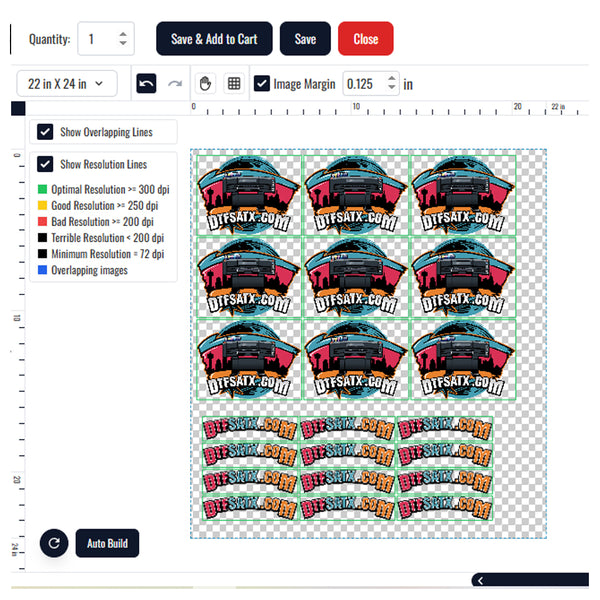

You can also contact dtfsatx.com to get high-quality custom DTF transfers quickly and affordably. They offer a user-friendly Gang Sheet Builder, which allows you to maximize your designs on a single sheet, saving you both time and money.

When To Choose DTG Printing?

DTG printing is ideal when your business needs high-quality, photo-realistic designs with fine detail on light-colored cotton garments. It is the perfect option for small to medium-sized batches or custom one-offs, offering a fast setup and simplified workflow with minimal need for pre-treatment.

If your products focus on premium, soft-feel apparel and your orders are not large-scale or require frequent customization, DTG is a perfect fit.

Final Words

I hope we helped you in deciding which printing method suits your business. Always consider your budget, technical aspects, and the specific demands of your business to achieve quality results.