Many people dig into the direct-to-film printing method for custom apparel printing, but they often overlook the most important factor of choosing the right DTF transfer sheet size. Sometimes, people realize too late that using the wrong sheet size leads to wasted material or slower workflows.

This guide helps you know different DTF transfer sheet sizes and factors to consider while choosing the right size.

What Is a DTF Transfer Sheet?

It is a special PET film sheet coated with a layer that allows designs to be easily printed on it using DTF ink. Later, one can use the sheet to print the design on the garment with the help of a heat press. These sheets work with a DTF printer, powder adhesive, and heat press to deliver high-quality results on cotton, polyester, blends, and hard surfaces.

Why Choosing the Right DTF Size Matters

Choosing the right DTF sheet dimensions is important because:

-

The right sheet size ensures minimal material waste. You will never leave a large blank space and use most of every film.

-

Larger sheets or rolls allow you to print multiple designs at once. It can reduce printer reload time and speed up your workflow.

-

Efficient use of space and material means lower costs per print, especially for bulk orders.

-

Matching the sheet size to your design prevents cropping or awkward placement on garments.

Common DTF Transfer Sheet Sizes

Here are a few common direct-to-film transfer sizes:

A4 Size (8.3” x 11.7”)

They are ideal for small logos, pocket prints, sleeves, and caps printing. It is especially suitable for home-based businesses and custom small-batch printing.

-

Pros: Easy to handle, less expensive per sheet.

-

Cons: Limited print area.

A3 Size (11.7” x 16.5”)

A3 transfer size is best for full chest designs, tote bags, and back prints. If you have a medium-sized print job, you can go for A3 transfer sheets.

-

Pros: Balanced in size and affordability.

-

Cons: May require more sheet changes during bulk printing.

A3+ Size (13” x 19”)

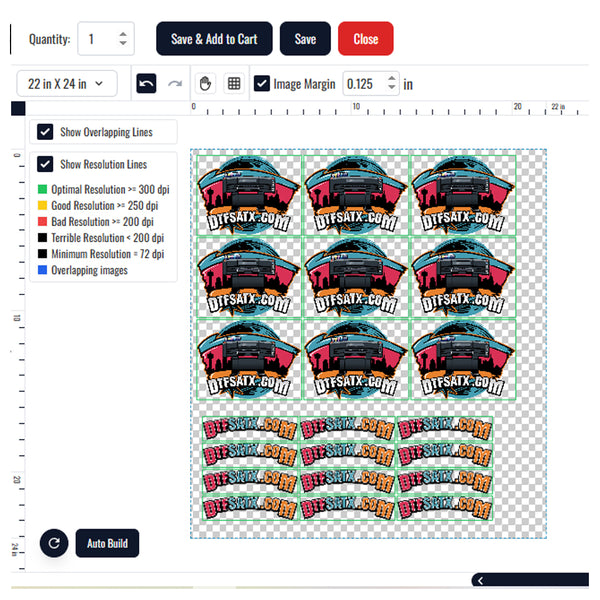

For large apparel, DTF or UV DTF gang sheets, A3+ is the best sheet size. It is suitable for semi-industrial use and higher productivity setups. If you want to order a customized gang sheet, contact DTF San Antonio.

-

Pros: Extra space for gang sheets or multiple designs.

-

Cons: May not fit standard desktop DTF printers.

Roll Size (typically 24” x 328ft or 60cm x 100m)

This roll size is best for industrial DTF printers, commercial-scale printing, and bulk production. You can use this for gang sheets, large-format designs, or continuous runs of multiple prints without frequent interruptions.

-

Pros: Continuous printing, high efficiency, less waste.

-

Cons: Requires a roll-to-roll DTF printer and space.

What Are Gang Sheets in DTF Printing?

DTF gang sheets are large transfer films where multiple designs are arranged together. They are a smart way to maximize the use of your DTF film, especially with A3+ or roll sizes. If you print a variety of logos or graphics for different items, gang sheets save time and reduce waste.

Factors to Consider When Choosing DTF Sheet Size

Here are a few considerations when choosing the DTF heat transfer sheet size: Make sure to read how does DTF printing work:

Printing Equipment Compatibility

You need to ensure your DTF printer supports the size of film you intend to use. Not every printer accommodates A3+ or roll sizes.

Design Dimensions

If your designs are mostly small (like sleeve or cap prints), A4 sheets are economical. For full-size t-shirt graphics, A3 or A3+ may be more appropriate.

Order Volume and Workflow

If you have smaller or custom orders, A3 or A4 sheets are more suitable. However, high-volume production goes well with roll films.

Material Cost and Budget

DTF rolls offer better long-term value but they have a higher upfront cost. A4 and A3 sheets are more accessible for small occasional orders or startups.

Storage and Handling Space

Roll films require more space for storage and handling, but pre-cut sheets are easier to store and transport, especially for smaller setups.

DTF Transfer Sheet Sizes for Different Use Cases

|

Use Case |

Recommended Sheet Size |

Why? |

|

Pocket Logos & Tags |

A4 |

Compact and cost-effective |

|

T-Shirt Fronts/Backs |

A3, A3+ |

More space for mid-size designs |

|

Bulk Printing |

Roll Size |

Higher efficiency, ideal for gang sheets |

|

Mixed Design Batches |

A3+ or Roll |

Suitable for gang sheet arrangements |

|

Home Business |

A4 or A3 |

Easy to manage, low investment |

Tips to Optimize Your DTF Workflow with the Right Sheet Size

Here are a few tips to make the most of your DTF film size:

-

You should use gang sheets efficiently by arranging multiple designs on a single sheet to maximize space and reduce waste.

-

Always leave consistent spacing between designs to ensure clean cuts and avoid overlapping, especially when printing on larger sheets or rolls.

-

Tools like Adobe Illustrator or CorelDRAW help you tightly arrange elements on your sheet, giving you greater control over spacing and sheet utilization.

-

For small logos or patches, stick with A4; for full-shirt graphics or varied designs, go with A3+, gang sheets, or rolls to reduce handling time.

FAQs

Can I cut DTF transfer sheets into smaller pieces?

Yes, you can cut larger sheets into smaller sections if your design allows it. Be cautious not to damage the print.

Is there a difference in print quality between sheet sizes?

No, print quality depends more on your printer settings, ink quality, and heat press, not the sheet size.

Are roll DTF films reusable?

No, when you transfer the printed photo onto the fabric, you cannot use that DTF film again.

Final Thoughts

If you use the perfect size of DTF transfer sheet for your business, you can manage the cost easily, minimize waste, and fulfill customer needs efficiently. Whether you are a small startup or a growing custom apparel business, managing your sheet size is a smart way to boost productivity and profits.